Safety Light Curtains

As a manufacturer of safety light curtains for more than 45 years, Wintriss builds light curtains for the toughest applications. Our Shadow light curtains withstand the rigors of the pressroom, including severe shock, mechanical abuse, and lubricant spray. With nearly 50,000 systems installed, the Shadow has a proven track record.

Shadow® 9 Safety Light Curtain Features:

- Specifically built for the pressroom

- Rugged, IP67 rated housing for maximum environmental protection

- No control box is needed if connected to WPC 1000 or WPC 2000

- Connect up to 3 pairs of heads to a WPC 1000 or the optional control box, or up to 6 pairs of heads to a WPC 2000

- Rugged extruded heads - only 1.5" x 1.5", in lengths from 9" to 59"

- Easy-to-use Programmable Blanking

- Optional high-visibility multi-color (red, yellow, green) state indicator lamp

- Category 4 for High Risk Hazards

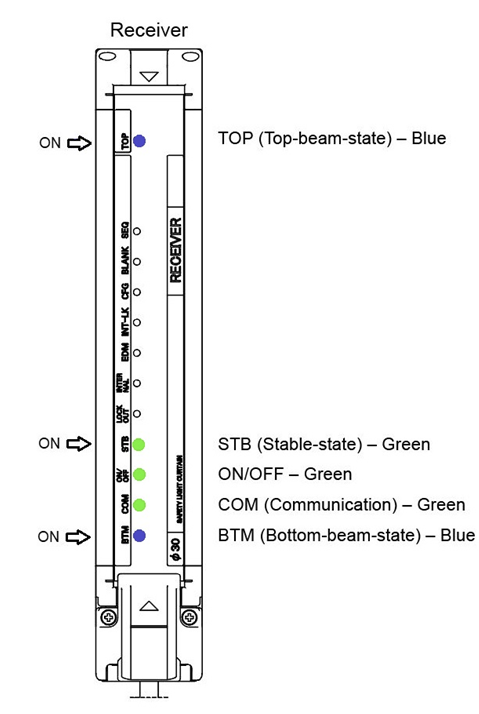

- Diagnostics LEDs

- Easy to align with LED alignment indicators

- 2 cross-checked PNP safety outputs

- 2-year warranty, 48-hour service turnaround

Optional Shadow 9 Light Curtain Control Box Features

- Two cross-checked captive contact stop relay outputs

- 24VDC power supply for the light curtain heads

- Key switch for programming fixed blanking windows

- Dry-contact auxiliary output for non-safety applications like a beacon or alarm

Shadow 9 Light Curtain heads connect directly to the WPC 1000 and WPC 2000 press controls. For press guarding applications, up to 3 pairs of Shadow 9 Light Curtain heads can connect directly to the WPC 1000 and up to six pairs to the WPC 2000 Wintriss Clutch Brake Control - with no need for a separate control box. This reduces both the initial investment in equipment and the cost of installation.

Connect up to Three Pairs of Light Curtain Heads to One Control

Shadow 9's unique design enables you to protect multiple sides of a machine using a single control, one pair of cables, and up to 3 pairs of light curtains in series. You can protect both the front and back of your equipment as well as provide one-side horizontal pass-through detection. Even a large machine can be guarded with up to 177" of protected zone to a single control providing an economical solution and minimizing installation time.

Programmable Fixed Blanking

Fixed blanking windows disable one or more beams to allow stationary objects such as conveyors or work tables to remain in the sensing field. You simply place the obstruction between the transmitter and receiver and turn the key-lock switch on the control. Shadow 9 senses the presence of the object and "blanks" the obstructed beams. When the obstruction is removed, the system will not allow the machine to run until the control has been reprogrammed to "unblank" the beams.

Fixed blanking windows may span any number of beams, but there must be at least two consecutive beams unblanked on each pair of safety light curtain heads; also, on the first pair of heads either the top beam, bottom beam, or both must remain unblanked.

Floating Blanking Window

Shadow 9 also enables you to set a floating blanking window, one beam wide, to allow objects smaller than 1", such as air-ejected parts, to pass through the safety light curtain in a random pattern without interrupting operation. This can also be useful when air or hydraulic lines need to pass through the field. You can use both floating and fixed blanking simultaneously.

3rd Party Verifications

Instead of saying "designed to meet," at Wintriss we felt it was important to subject our systems to the toughest third-party certifications. The Shadow 9 Safety Light Curtain has undergone independent testing and certifications by Underwriters Laboratories (NRTL/C) to CAN/CSA 22.2 No. 14 and CAN/CSA 22.2 No. 0.8 and by TÜV to Category 4 CE/IEC 61496-1 and CE/IEC 61496-2. The Shadow 9 Light Curtain complies with OSHA 1910.217, ANSI B11.1-2009, ANSI B11.19, CSA Z142 and CSA Z432.

Optional Splatter Shields

The optional splatter shield offer lens protection when the light curtain heads are installed near welders or or in high grease and oil exposure applications. The shields are available for all sizes, and are easy to install – They attach to heads with clips (included in the kit).

Service and Support

It’s necessary to have a thorough understanding of the various safety regulations when applying a safety light curtain system in your application. Both factory personnel and our representatives keep up with these changes. At your request we will check out your application and make recommendations for the proper light curtain configuration as well as any supplemental guarding that may be required. All of our light curtain systems carry a 2-year warranty. If a system does go down, we have a 48-hour turnaround policy on repairs.

Wintriss' commitment to pressroom safety began more than 45 years ago when it first started manufacturing light curtains. Contact Wintriss for more information or assistance in protecting your pressroom employees with Shadow 9 Safety Light Curtains.