Coleman Machinery - The Fabrication Experts

Ironworker Tooling

Acrotech, Alinder, All Steel, Alfra, Alva Allen, Alternative Punch, Armstrong Blum, Baileigh, Baker Group, Bateman, Batey, Beatty Bully, Brobo, Clausing, Cleveland Steel Tool, Controlled Automation, Davco, Durma, Davis, Di-Acro, Dcorak, Eagle Fabricator, Edwards, Enerpac, Ermack, Excel, Fab 1-1, Fabmaster, Fabricator, Fabriline, Fabripunch, Falcon, Fecep, Foremost Megapress, Franklin Mfg, Gabro, Gairu, Gardner-Bender, Geka, Gladiator, Greenlee, Grizzly, HMI, HTC, HAWTHORNE, HELLER, HENDLEY & Whitemore, Hercules, Hill Acme, Hills & Jones, Honeoye Industries, Hougen-Ogure, Husky, Inflation Fighter, Iron Crafter, Iroquois, Izumi, Julius Blum, J.F. Kidder, J.F.Y. Foremost, Kingsland, Kling, Knuth, Lansing, Leading Tech, Lehman, Magnum, Manco, Megaworker, Metal Fabricating Systems, Metal Master, Metal Pro, Meyer, Midwest Manufacturing, Mubea, Nelson, Nitto Kohki, Ocean Clipper, Omera, Omes Promaco, Panelmaster, Peddinghaus, Pittsburgh, Polamco, Power Team, Pressmaster, Promaco, Profel, Puma, Rogers Manufacturing, Roper Whitney, Rotex, J.T. Ryerson, Sahinler, Stochman, Segma, Shark, Simplex, Sizor, Son Tag, Spartan, Springwater, Trjoan, Uni-Hydro, Wysong.

Fabrication

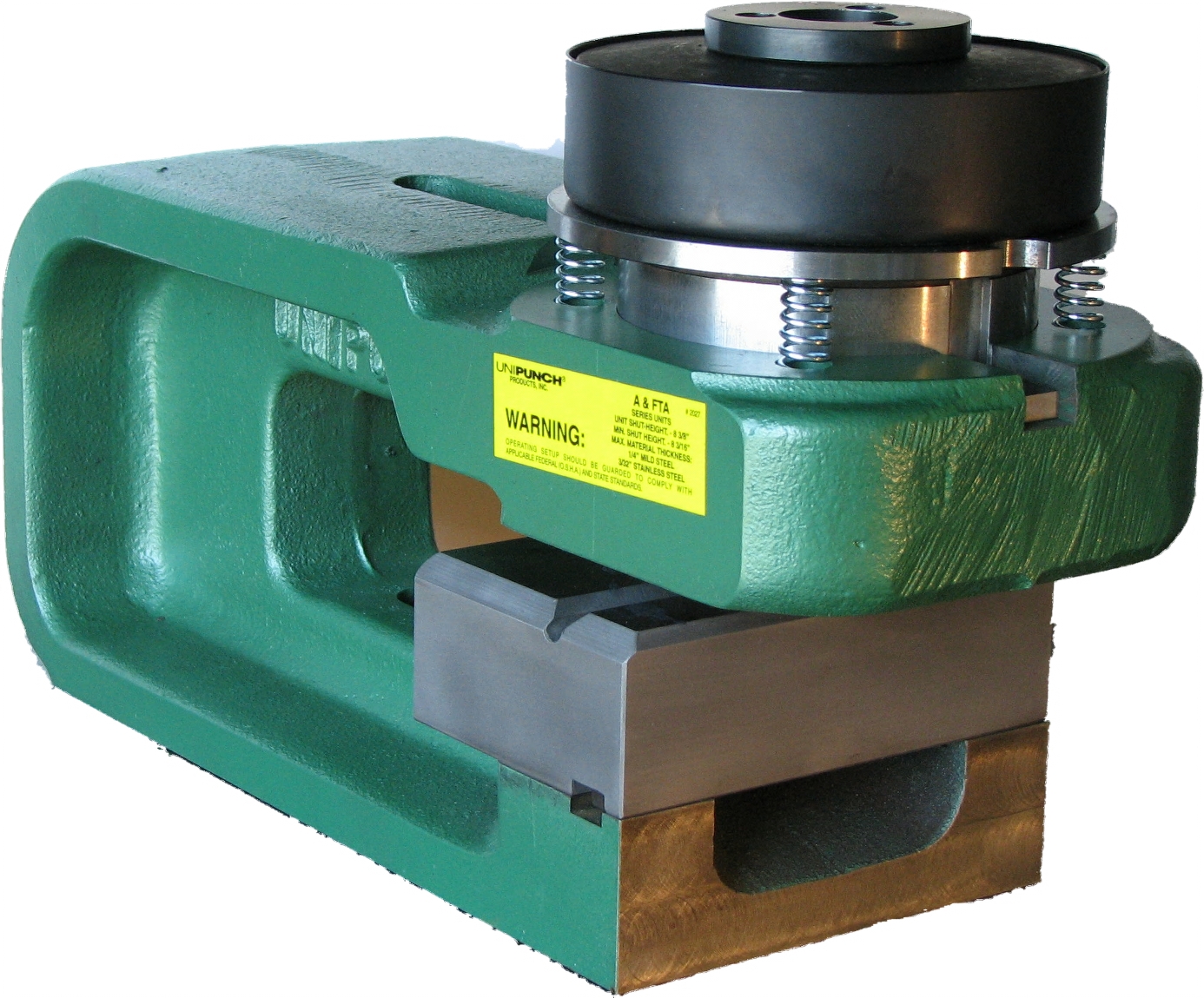

UniPunch C-Framing

UniPunch tooling is commonly used for punching holes in aluminum extrusions up to 1/4" thick. While many of our clients use our standard tooling to punch extrusions, UniPunch frequently modifies the pedestal die and/or holder to accommodate special shaped parts. The UniPunch Feed Clearance Units and "AJ" Series are ideal for punching holes in aluminum extrusions. They feature a pedestal style die for punching close to the leg of an extrusion.

5000 & 5100 Bed Rails – for mounting UniPunch A or B series tooling in press brakes. Primarily used for straight line hole punching and accepts ½” (12.7mm) thick strip templates to accurately position the pilot pins of UniPunch units or Unispacers for prototype applications. Bed rails are available in lengths up to 12’ long and the 5100 bed rail will accept a press brake bending die. Contact niPunch for custom lengths to fit your press requirements.

5110 Bed Rail – for mounting UniPunch G series fixed base or adjustable base tooling in press brakes. This bed rail contains one front T-slot and a top surface mounted bar key that is compatible with the G series unit bases.

5202 Quick Die Change and Clamping System - For mounting UniPunch A or B series tooling in press brakes. This base plate system is designed for use with dovetail style templates dedicated to your specific part hole pattern. The template can be quickly locked into position utilizing built in clamps for fast changeover of tooling

at the press. Simply slide-lock-punch. The 5202 system is available

in lengths up to 12’ long.

T-Slotted Plates - for mounting UniPunch A or B series tooling in presses with large bed and ram areas. These steel plates are available in widths from 12” to 30” for punching and notching larger parts and for parts with complex hole patterns. The thin template or template over die method is recommended when mounting UniPunch tooling onto T-slot plates.

Automec

-

CoastOne Press Brakes -Automec, Inc. is a Certified USA Dealer of CoastOne electric press brakes. (servo-electric) Automec handles sales and service for customers in the U.S, as they have been with their back gauge systems for the last 47 years. CoastOne electric press brakes are becoming the future of press brake technology. The technology behind the CoastOne electric press brake is the “direct-drive system,” which uses servo motors directly tied to ball screws to administer force. This capability, in turn, offers an extreme accuracy of 0.000079 inches!

-

Backgauging Systems -Our backgauge systems consist of a programmable control where the operator enters a dimension and a motorized gauging mechanism automatically moves through a sequence of programmed dimensions. Our systems also offer program-ability of the ram for many pressbrakes. They can offer programmable "top of stroke," "slow speed," and "bottom of stroke." Our systems can be retrofitted to existing pressbrakes, shears, and punches.

-

TigerStop Systems -Whether your looking for a simple and accurate stop for the shop and job site, or you need a monster system to handle structural steel with 0.008" (0.2mm) accuracy which you can control via a networked CAD system, TigerStop has the solution for you.

-

Squaregage Systems -Studies show that the majority of shearing time is consumed in set-up…not shearing. SQUAREGAGE reduces that set-up time and increases shear productivity, especially when accurate square blanks are required.

-

Shearfeed Systems -The PS 50 Autofeed is a programmable feeding device for shears. It grips the workpiece with pneumatic fingers, feeds the piece into the shear with precision movements and fires the shear when in position. The common application is reshearing multiple patterns created on a CNC punch but it can also be used for cutting strips of material.

Specific Press Brake Dies

Since 1996, Specific Press Brake Dies is committed to providing general purpose and custom designed press brake tooling to maximize the productivity of your press brake. With over 80 years of combined engineering experience, Specific Press Brake Dies has a reputation for providing quality, value, integrity and service that exceeds others in our industry.

Specific uses only the highest quality press brake die material to manufacture accurate, long lasting press brake tooling to ensure consistent quality. Offering all types of the worlds most common tool styles (including American standard, European, & Wila New Standard) Specific can meet your needs with any of your particular requirements whether that be easy bends to multiple bend highly customized tools.

We produce many different types of die sets, including:

- Offset Die Sets

- Joggle Die Sets

- Channel Die Sets

- Curling Die Sets

- Wiping Die Sets

- Rib Forming Die Sets

- Radius Forming Die Sets

- Special Offset Die Sets

- Hemming / Standing Seam Die Sets

We produce many different types of punches & dies, including:

- 90 Degree Forming Punches & Dies

- 90 Degree Air Forming Punches & Dies

- Gooseneck Punches

- Acute Forming Punches & Dies

- Flattening Dies

- Pivot Form Vee Dies