Wintriss WPC 2000 - Option 2 Expansion Module

WPC 2000 - Option 2 Expansion Module

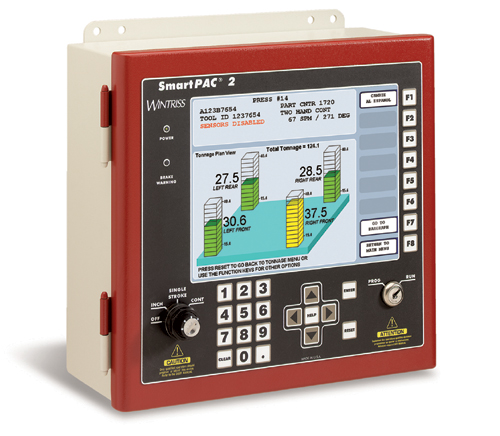

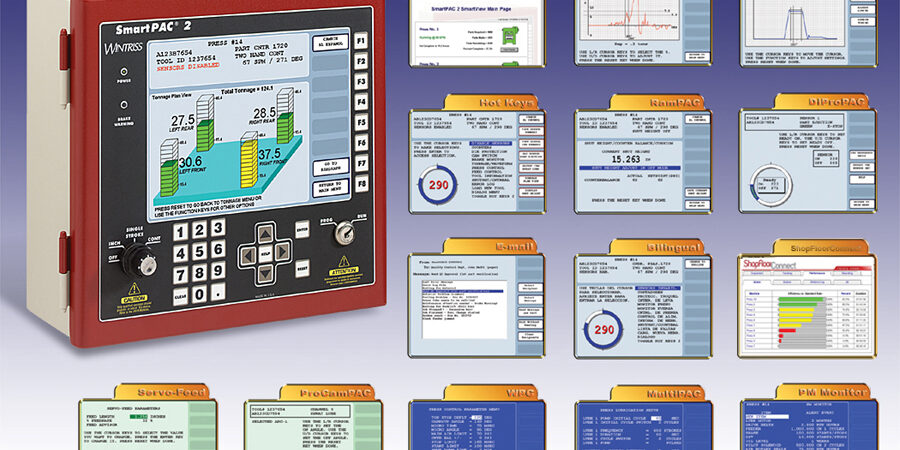

Expansion Module For WPC 2000 Integrated With SmartPAC 2.

The Option 2 Expansion Module for the WPC 2000/SmartPAC 2 provides additional press control functions for a reasonable cost.

Features include:

- 20 additional user-defined inputs

- 4 additional pairs of user-defined cross-checked inputs

- Hydraulic overload control

- Flywheel brake control

- Motor current readout (if equipped with an optional sensor)

- Lube system control optional

- Speed control optional

Additional User-Defined Inputs

The Option 2 Expansion Module features 20 user-configurable inputs (in addition to the 7 already present in the WPC 2000) that can be used to monitor ancillary press functions. In addition, the Option 2 provides 4 pairs of cross-checked inputs (in addition to the 2 already present in the WPC 2000) for monitoring safety applications.

Hydraulic Overload Control

Developed for presses equipped with an hydraulic overload system, this standard Option 2 feature emergency-stops the press when a hydraulic overload occurs and provides the logic necessary to reset the system.

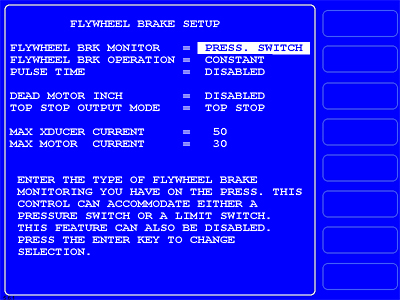

Flywheel Brake Control

On presses equipped with a flywheel brake, Option 2 can monitor a pressure or limit switch to ensure that the flywheel brake is released or engaged at the proper time. If the optional Speed Control (see below) is used, the flywheel brake can be pulsed for a specific amount of time.

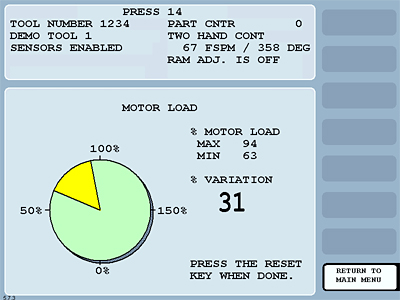

Motor Current Readout

When wired to an optional current sensor, Option 2 provides a numeric high-and-low-value readout for motor current (% load) during a stroke. This information is useful for manual counterbalance pressure adjustments.

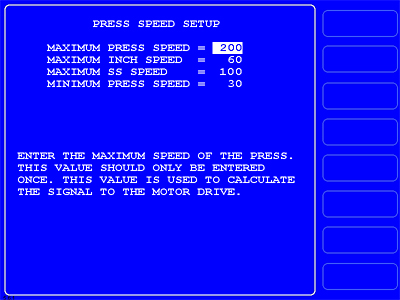

Speed Control

Controls the speed of variable speed presses equipped with either eddy current or frequency drives. Precise speeds for each mode (Inch, Single-stroke and Continuous) are conveniently entered and stored in the SmartPAC 2’s memory for each tool. Press speed changes automatically when you change the mode, eliminating the need for speed pots and meters on the press console.

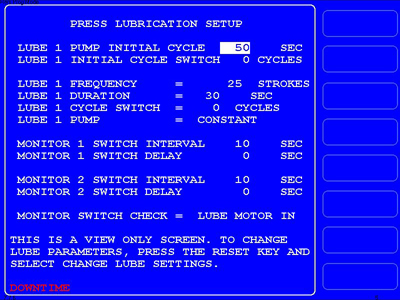

Lube Control

You can control, program, and monitor a lube system that is designed to dispense an initial coating of lubricant to press components (for example, the counterbalance cylinders) that require a controlled amount of lube before the press begins to operate.

In addition, the Option 2 board can monitor up to two additional lube systems - such as those for main bearings, gibs, etc - that should operate continuously once a selected device (such as the main motor) is actuated.