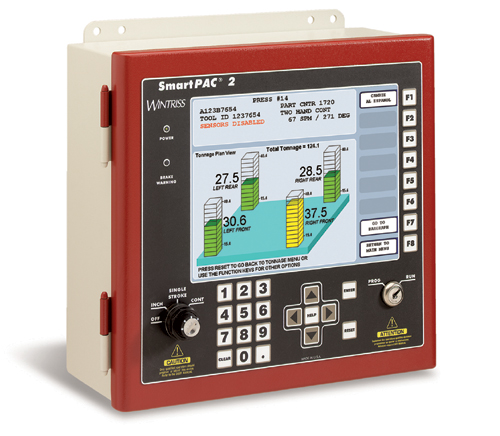

Wintriss DiProPAC Die Protection Module

DiProPAC Die Protection Module

Advanced features make the DiProPAC the most effective device of its kind in the world.

Die Protection System

Wintriss die protection systems help to prevent costly repairs and press downtime. With sensors installed in and around the tool, malfunctions such as improper part ejection, misfeeds and material buckling are detected before die damage occurs.

If there is a malfunction, the die protection system signals the press to stop. The Wintriss Controls Group pioneered the use of electronic sensors for die protection and introduced the first commercial die protection systems more than 40 years ago. Wintriss remains the leader in die protection systems and technology.

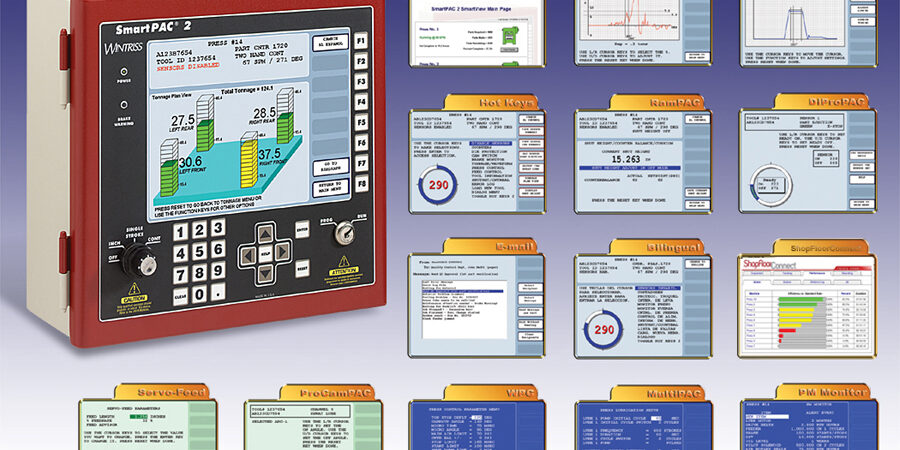

- Saves up to 200 die protection tool settings

- 8 or 16, or 32 programmable sensor inputs

- Allows "on-the-fly" adjustments

- Sensor actuation signals shown on screen

- Individual stop selection for each sensor (emergency or top stop)

- LCD circle diagram represents press stroke for ease of programming

- Individual "ready" signals for each sensor

- Ability to custom-name sensors for easy identification

- Die-protection error diagnostics

Die Protection Sensors: Photoelectric, Fiberoptic and Proximity

Wintriss offers a complete line of die-protection sensors for in-die use. These sensors are rugged, shock-resistant and sealed against the environment. Sensors are available to detect everything from end-of-the-coil to misfeed to part-ejection.