PA Accessories

PNEUMATIC TRANSPORTER

This Unique Beltless Conveyor

Transports pieces of scrap, or parts, with a shaking motion. A custom tray is fitted onto the body and the rhythmic, linear motion moves the tray slowly forward and then quickly backwards. The metal shavings, scrap, or finished parts are gently shuffled along the tray and into a convenient container.

Air Consumption is so low that it is considered insignificant in a press shop environment. The noise level is well under acceptable standards for industrial uses.

Note 1: Recommended speed; 120 SPM

Note 2: Feed Rate; 26-34 FPM (8-10m/min.)

Note 3: Air Pressure Range; 60-75 PSI (4-6 bar)

Note 4: Max. incline of Tray 8 Degrees.

Design a Custom Tray configuration to suit your application.

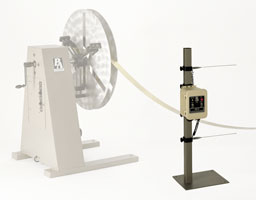

STOCK DETECTOR

Reduce Die Breakage and Machine Downtime

Prevent the smashup of ONE die and this sensor pays for itself. The P/A Stock Detector uses a resistance-sensing controller to monitor material position as it enters the press or moves through the die.

Or probes to signal either an Emergency Stop or Top Stop of the press. Stock buckling, run-out, and misfeeds are detected before a serious problem develops. P/A will help you select the probes and sensors best suited to your application.

RF SYSTEM

The RF System Uses a Shielded Antenna

And a Radio Frequency Field to sense conductive material. As the loop changes height, the radio signal changes in response causing the variable DC drive of the Reel or Straightener to maintain a constant loop.

Is not susceptible to Ultrasonic interference which makes it an attractive alternative to sonar sensing systems.

ULTRASONIC

The P/A Ultrasonic Loop Control Utilizes Sonar, Or "Echo Location"

To determine and maintain a constant loop height. This gives the operator the flexibility of using the longer loops required when stamping long progressions.

While the coded sound bursts reject interfering sound waves.

LOOP CONTROL

The LC-2 is an ON/OFF Electronic Limit Switch

Sensing vertical movement in a slack loop of conductive material. Spring probes maintain smooth stock delivery between the adjustable upper and lower limits.

Designed to interface with a variable speed AC or DC drive. The drive changes speed automatically in response to signals from the touch probes for smoother payoff and take-up. The LC-3 can also be converted to a No-Touch Sensor System with the use of proximity sensors, which are available upon request.

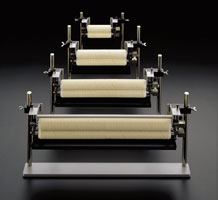

STOCK OILER

Accomodates Material .001-.187"

The P/A Stock Oiler increases your die life and eliminates the "coffee-can" mess to make your operation safer and more efficient. Oil flow to both rollers is individually controlled by metering valves which are installed on the reservoir tank. Adjustable tension springs help to apply the right oil film by supplying enough pressure to squeeze off any excess which is then recycled to the unit.

Pivots to accommodate material movement and crown, camber, or unstraightened stock. Mounting between the press feed and tool is easily done by attaching a magnet to the steel base, or by drilling two holes. Two wing nuts allow for quick pass line height adjustment to suit different tools.

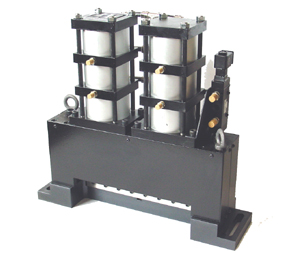

HYDRAULIC STOCK CUTTER

P/A's Hydraulic Stock Cutter is perfect for use in Cut-To-Length applications that are running thicker material.

A Four-Way Solenoid valve controls the sequencing and can be synchonized with the press. These Stock Cutters are designed to shear at full width. Mount them on the press to use as a scrap cutter or part cutoff. The hydraulic power pack and cylinder deliver smooth, effective force.

Upper and Lower Blades are vertically adjustable for wear compensation and sharpening. The lower blade is also horizontally adjustable to provide the correct blade clearance for cutting different materials.

Note: Input power is 220/3 Phase, 400/3 Phase, or 440/3 Phase. Please specify.

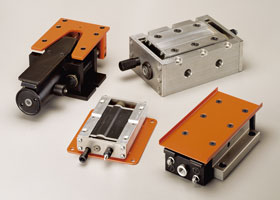

COMPACT PNEUMATIC STOCK CUTTER

Maintenance Free Compact Pneumatic Stock Cutter

Innovative new design, maintains close tolerances between parts and extends cutting blade life, lasting typically five times longer than competitive models.

MECHANICAL SCRAP CHOPPER

Unique Helical-Ground Blade

This unit chops a wide variety of materials from paper to cold rolled steel without adjustment. Once installed, any number of stock thicknesses can be fed into the chopper without any additional set-up time.

The reel-type scissor action reduces off-center loading by chopping a width of only 14 times the maximum material thickness at one time regardless of total stock width.

PNEUMATIC STOCK CUTTER

Can Be Used In Cut-To-Length Applications

When fed by a programmable Servo Feed or Air Feed. Mounted on a press, it serves as a scrap cutter or part cutoff. Pneumatically powered, these Stock Cutters are designed to shear material at full width. The powerful air cylinders have a pancake profile for High Speed Operations. The Four-Way Solenoid valve controls the sequencing and can be synchronized with a press.

Both upper and lower blades are vertically adjustable for wear compensation and sharpening. The lower blade is also horizontally adjustable to provide the correct blade clearance necessary to cut different materials. No other stock cutter has both of these features.

Note: Input power is 120 VAC, Single Phase, 50/60 Hz. Other voltages available, 240 VAC, 24 VDC.

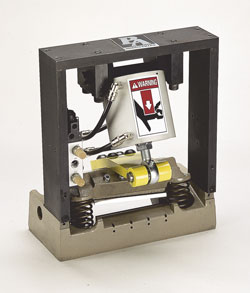

AIR SCRAP CHOPPER

Air Scrap Chopper

Using the same principle as our Ram Driven Mechanical Scrap Chopper, this pneumatically powered chopper is designed to shear scrap material from .004" (0.1mm) to .074" (1.8mm) thick mild steel.

Provides controlled chopping while integral dampeners absorb snap through shock. The helically ground upper blade, made of high chrome tool steel, shears nearly any kind of material. Note: Guard Removed for Photo

Note: Solenoid Voltage is 120 VAC, Single Phase, 50/60 Hz. Other Voltages available - 240 VAC, 24 VDC.