Vibro Dynamics

MICRO/LEVEL® Elastomer Isolators

Among the features are a super-strong one-piece housing; a high-strength steel bearing plate; a heat-treated adjustment screw that provides precision leveling and alignment; and a custom-molded elastomer that effectively reduces harmful vibration. Our elastomers are designed, compounded, and applied to resist creep and compression-set, and to maintain their resilience shape and dimension characteristics for the life of the installation.

Series 6 & 8 Vibration Isolators

Series 6 & 8 vibration isolators have load capacities up to 8,000 lbs/3560 daN for industrial machinery weighing up to 45 tons depending on the number of mounting points.

Series 9 to 26 Series Vibration Mounts

Series 9 to 26 Series vibration mounts are designed for machinery weighing up to 450,000 lbs./200.200 daN.

MXL and MXLP Leveling Vibration Isolators

MXL and MXLP Leveling Vibration Isolators and MXBP and MXBN Isolation Elements are for stamping press and other heavy industrial machines weighing from 113 to over 2270 metric tons. (250,000 to over 5 million lbs.).

MXBP and MXBN Isolation Elements

MXBP and MXBN Isolation Elements are for stamping press and other heavy industrial machines weighing from 113 to over 2270 metric tons. (250,000 to over 5 million lbs.).

Wedge Mounts

Wedge Mounts are elastomeric vibration mounts for punch press, die cast, and injection molding applications weighing up to 270 tons.

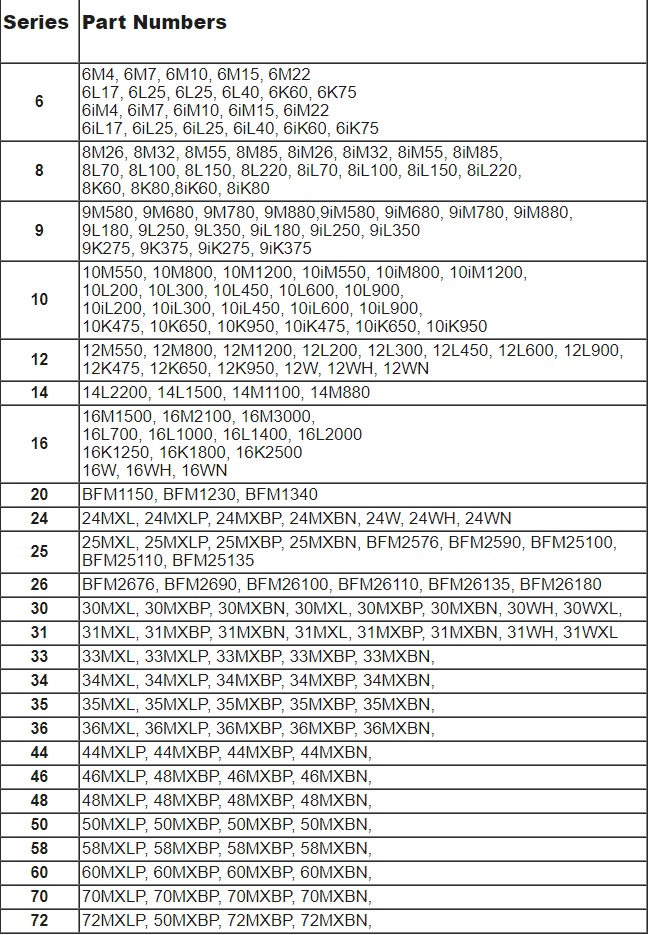

Isolator Parts Cross Reference

Wedge Style Isolators

Vibro/Dynamics Micro/Level® Wedge Style Isolators are designed for the free-standing installation of Punch Presses, Machine Tools, Plastic Injection Molding and Die Cast machinery.

Their wedge design, with side adjusting leveling screw, makes them ideal for leveling and installing machines that cannot use vertical leveling screw type isolators because the mounting holes are too small or nonexistent.

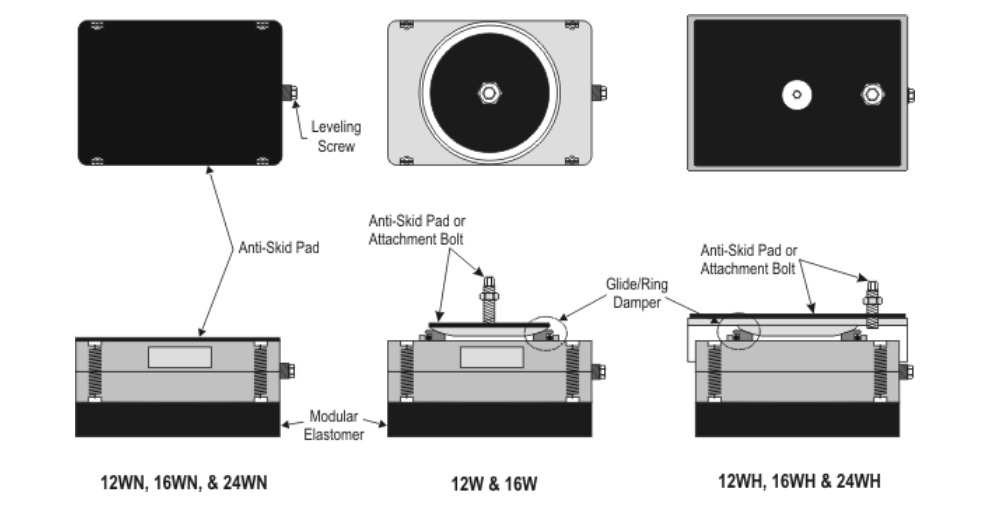

Wedge Isolators are also available with our unique Glide/Ring™ damper designed to dissipate horizontal forces that cause some machines to walk. The Glide/Ring damper’s built-in swivel automatically adjusts for an out-of-parallel condition between the foundation and bottom of the machine feet for improved machine support and isolator performance.

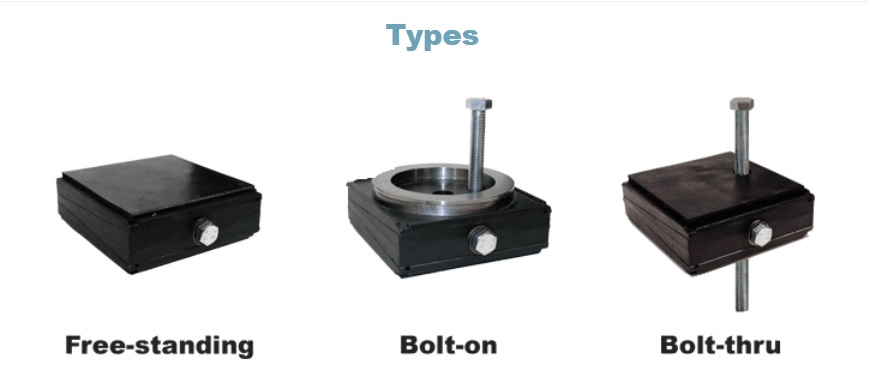

Wedge Isolators are available in free-standing, bolt-on, and bolt-thru styles with static load ranges from 4,600 - 144,000 lb. per isolator.

Multi-layer elastomer versions are available for added vibration and shock isolation. Custom types, models and configurations to suit just about any need.

Glide/Ring™ Damper

The Glide/Ring Damper is a unique device, available on some models, that provides uniform support and keeps machines from

walking. It consists of a Swivel Dish, Swivel Seat, Damping Ring and Retainer Ring.

The Glide/Ring Damper has two functions.

First, the Swivel Dish has a four degree tilt capability that automatically adjusts when the foundation and the bottom of the machine feet are not parallel. In an extreme out-of-parallel condition, one side of the isolator will compress more than the other, resulting in an uneven load pattern on both the machine’s foot and the isolator’s elastomer. The Glide/Ring damper provides uniform support for improved machine and isolator performance.

Second, the swivel seat is designed to move slightly in the horizontal direction, dissipating horizontal forces that cause some high-speed machines to walk.

Features and Benefits |

|

Nivell® Wedge Mounts

Nivell® wedge mounts are designed for machine tools, plastic injection molding machines, die casting machines, and various machines used in the printing, textile and food industries.

Vibration and Shock Isolation for the Forging Industry

Vibro/Dynamics manufactures a wide variety of products designed to isolated the transmission of severe vibration and shock forces commonly found in the forging industry. Isolating these forces protects your people and the work environment.

Forging Hammers, Forging Presses, and Screw Presses, have all been successfully installed on Vibro/Dynamics products. Precision machine tools, measuring equipment, induction heaters and furnaces have been installed on vibration isolators to further protect them from incoming vibration and shock.

FSV & FSX Hy/Damp™ Spring Isolators are low natural frequency, viscous damped, coilspring isolators that offer the greatestvibration and shock control possible. These isolators are alsoextremely effective for hammer and forging press applications. Viscous damping is very effective at reducing motion and absorbing the high energy levels found in hammer applications.

The MRM™ Isolation Systems are modular, layered elastomer isolation elements that are configured to provide a desired vibration and shock isolation level. Unlike other systems, these units are mechanically assembled using pins and bolts to prevent any unstacking of the elastomer layers that can occur in competitive systems. Specially compound elastomer modules provide high levels of isolation and damping while minimizing settling and creep.

VSC Spring Isolation for protection of forging furnaces and other equipment in high shock and vibration environments.

Low Frequency Elastomeric Isolators

Model: VBFB

- Multidirectional vibration/shock isolators

- Up to 1.2 in displacement under shock

- Transmissibility: Q < 6

- Max static load: 3g

- Between 8 and 14 Hz resonant frequency*

- Up to 0.05 in max peak output at resonance

- Superior temperature range: -20°F to +210°F

- Great adaptability/versatility

Model: VBFC

- Multidirectional vibration/shock isolators

- Up to 1.5 in displacement under shock*

- Transmissibility: Q < 10

- Max static load: 3g

- Between 5 and 10 Hz resonant frequency

- Up to 0.08 in max peak output at resonance

- Superior temperature range: -20°F to +210°F

- Great adaptability/versatility

Model: VBFJ

- Multidirectional vibration/shock isolators

- Up to 2.0 in displacement under shock*

- Transmissibility: Q < 10

- Max static load: 3g

- Between 7 and 13 Hz resonant frequency

- Up to 0.05 in max peak output at resonance

- Superior temperature range: -20°F to +210°F

- Great adaptability/versatility

Model: VBF

- Multidirectional vibration/shock isolators

- Up to 1.8 in displacement under shock

- Transmissibility: Q < 10

- Max static load: 3g

- Between 10 and 12 Hz resonant frequency

- Superior temperature range: -20°F to +210°F

- Great adaptability/versatility

Model: VBFN45

- Multidirectional vibration/shock isolators

- Between 1.8 and 2.2 in displacement under shock

- Transmissibility: Q < 10

- Max static load: 3g

- 5 Hz resonant frequency for nominal load

- Superior temperature range: -20°F to +160°F

- Great adaptability/versatility

Model: VBF45

- Multidirectional vibration/shock isolators

- Between 1.8 and 3.0 in. displacement under shock

- Transmissibility: Q < 10

- 6 Hz resonant frequency for nominal load

- Superior temperature range: -20°F to +200°F

- Great adaptability/versatility

SVX, SVXN, SVS and SMS Series Hy/Tuned™ Spring Isolators

SVX, SVXN, SVS and SMS Hy/Tuned™ Spring Isolators are designed to solve the toughest vibration and shock control problems. These Spring Isolators have natural frequencies that are lower than elastomeric type isolators, making them the ideal solution for severe vibration and shock problems typically associated with large stamping presses doing heavy blanking operations.

These Spring Mounts are also used as seismic isolation elements under isolated foundations and concrete slabs. Spring Mount designs are also available to protect machinery and buildings from the damaging effects of earthquakes. We have many successful installations in earthquake zones.

SVX, SVXN, SVS and SMS Spring Isolators feature integral leveling or non-leveling, and viscous or material damping versions.

Key Features

- Viscous or Material Damping

Selecting the proper damping is essential for control of machine motion. That's why Hy/Tuned Spring Isolators are available with either Viscous or Material damping.- Viscous damping systems provides a higher degree of damping to control motion caused by inertia, braking or clutching. Viscous damping is recommended for machines that generate moderate to severe rocking forces. A good example is a single crank or eccentric, non-counterweighted press.

- Material damping systems are economical and recommended for machines that have a limited rocking forces and low inertia. Good examples are two and four point presses that have counter-rotating crankshafts or eccentrics that balanced each other out and have a low percentage of moving weight relative to the total press weight.

- Extra Vibration Protection and Uniform Support

Unlike conventional spring mounts, Hy/Tuned Spring Isolators come equipped with a high-quality resilient cushion that provides a uniform contact surface between the isolator and the floor. This cushion also isolates high-frequency vibration caused by coil spring resonance. - Built Tough to Last

Vibro/Dynamics combines its proven low-stress isolator design philosophy with high-quality materials to ensure the longest effective isolator life.

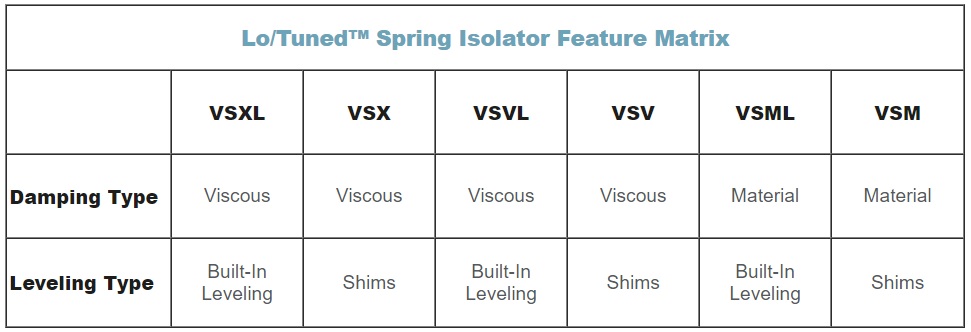

VS Series Lo/Tuned™ Spring Isolators

Product Summary

Vibro/Dynamics Lo/Tuned Spring Isolators feature a low frequency (2-3 Hz) design that is extremely effective in protecting sensitive areas from incoming vibration and shock. These Spring Mounts and anti-vibration isolators also effectively isolate the transmission of vibration and shock emitting from high-speed machinery.

Lo/Tuned™ Spring Mounts come with either material or viscous damping, and an optional

built-in leveling feature is also available.

Typical Applications include:

- high-speed presses,

- turret punch presses,

- dynamically-balanced presses,

- generators, compressors, pumps

- measuring equipment,

- isolated foundations,

- HVAC equipment,

- textile machinery,

- gear shapers and hobbers,

- other high-speed machinery with low inertial force.

Key Features

- Built-in Precision Leveling Feature Available

VSML, VSVL and VSXL Series Lo/Tuned™ Spring Isolators are equipped with precision leveling screws for fast and easy leveling. Precision leveling means better alignment of machine components, resulting in increased machine accuracy and improved machine and tooling life. This built-in leveling capability lets you get into production faster by leveling your machines with far greater accuracy than the trial and error method offered by shims or grout. - Viscous or Material Damping

Selecting the proper damping is essential for control of machine motion. This is why

Lo/Tuned™ Spring Isolators are available with either Material or Viscous damping.- Viscous damping systems are best suited for machines that pass through resonance slowly and have large out-of-balance forces relative to machine weight or whose operating speed is close to the natural frequency of the isolation system (resonance).

- Material damping systems are best suited for machines that: have small out-of-balance forces relative to machine weight; pass through resonance quickly; and operate at least 1.42 times above the natural frequency of the isolators.

- Extra Vibration Protection and Uniform Support

Unlike conventional spring mounts, Lo/Tuned™ Spring Isolators come equipped with a high-quality resilient cushion that provides a uniform contact surface between the isolator and the floor. This cushion also isolates high-frequency vibration caused by coil spring resonance. - Built Tough to Last

Vibro/Dynamics combines its proven low-stress isolator design philosophy with high-quality materials to ensure the longest effective isolator life.

Call Us Today 972-355-9000

Contact us for more informations!