Over 40 years experience and 40,000 security systems installed

WPC 2000 - Wintriss Clutch / Brake Control

The WPC 2000 clutch/brake controls is your best choice for press safety, reliability and support.

The WPC 2000 Clutch/Brake Control is an easy-to-use, dual microprocessor based system that controls a part revolution clutch mechanical power press. With its two independent microprocessor systems, the WPC 2000 provides diverse redundancy, the best technology in maintaining optimum clutch/ brake control and greater operator safety.

The WPC 2000's resolver eliminates the need for a mechanical rotary limit switch, and brings all timing adjustments to the operator control panel.

To increase productivity, the digital readout displays key information, such as press speed, stopping time and comprehensive error code diagnostics. And its crank-angle clock dynamically indicates the position of the crankshaft, whether the press is running or at rest.

Meets or exceeds all ANSI B11.1-2009 and OSHA 1910.217 regulations, including Control Reliability.

WPC 2000 Integrated with SmartPAC 2

The WPC 2000 can be combined with a SmartPAC 2 to seamlessly integrate all of your press control, automation, and monitoring functions. The WPC 2000/SmartPAC 2 integration provides a comprehensive user interface for all WPC 2000 functions and WPC 2000 initialization.

You can enable and set Micro-Inch, and program important press control parameters from using the SmartPAC 2 keypad. In addition, SmartPAC 2 provides an on-screen diagnostics display that shows the status of all of the inputs and switches.

You can expand the functionality of the SmartPAC 2 / WPC 2000 integration with the Option 2 Expansion Module.

WPC 2000

- Interrupted stroke provision significantly improves pressroom productivity

- Internal brake monitor checks press-stopping performance

- 9 Customized status codes (including 2 cross-checked pairs) installed by user

- Micro-inch capability improves set-up

- Self-diagnostics identifies control problems

- Can be integrated with SmartPAC® for greater ease of use (see screen shots below)

- Optional Auto-compensated Top Stop (ACTS) adjusts the top-stop angle automatically as press speed changes or the brake wears.

- Optional Shadow® light curtain provides point-of-operation guarding

- Optional Foot Switch, One-Hand Control, External Trip, Continuous-on-Demand and Bar Modes for maximum flexibility

- Optional Auxiliary E-Stop Relay Outputs for stopping or preventing from starting up to three auxiliary devices like a feed or a transfer if any e-stop button is pressed, any light curtain is interrupted or any cross-checked input is open.

WPC 1000

- Meets or exceeds all ANSI B11.1-2009 and OSHA 1910.217 regulations, including Control Reliability.

- Resolver-based, for accuracy and long-term reliability

- High-visibility LED crank angle and speed display

- Built-in real-time brake monitor to monitor stopping performance.

- Interrupted stroke provision significantly improves pressroom productivity

- Micro-inch capability improves set-up

- 3 available user-defined inputs (including 1 cross-checked pair for safety applications)

- Self-diagnostic capability quickly identifies problems

Optional Features and Accessories

- 6-digit counter with a preset

- Two-channel programmable cam

- Die block kit

- Shadow® 8 light curtains for point-of-operation guarding

- Operator stations and T-stands

- Optional Foot Switch, One-Hand Control and Bar Mode switches for maximum flexibility

Shadow 8 Safety Light Curtains

The Latest Safety Light Curtain From the Press-Guarding Experts.

Wintriss has been building the Shadow light curtains for the toughest applications for more than 40 years. Our light curtains withstand the rigors of the pressroom, including severe shock, mechanical abuse, and lubricant spray. With more than 45,000 systems installed, the Shadow has a proven track record.

Shadow® 8 Features:

- Smarter Next Generation Design

- No control box is needed if connected to the new WPC 1000 or WPC 2000

- The heads are Type 4 control reliable - The main receiver has 2 safety PNP outputs

- Connect up to 4 pairs of heads to a WPC or an optional control box with two cables

- Rugged extruded heads - only 1.5" x 2", in lengths from 12" to 59" (extensions from 9")

- Programmable fixed, and 1-beam floating blanking windows

- Type 4 CE approval

- Diagnostics display

- Easy to align with individual beam indicators

- 2 cross-checked PNP safety outputs

- 2-year warranty, 48-hour service turnaround

Optional Shadow 8 Control Box Features

- Two cross-checked captive contact stop relay outputs

- 24VDC power supply for the light curtain heads

- Two key switches for programming fixed blanking windows

- Dry-contact auxiliary output for non-safety applications like a beacon or alarm

Shadow 8 Heads Connect Directly to New WPC 1000 and WPC 2000 For press guarding applications, up to 4 pairs of Shadow 8 heads can connect directly to the new WPC 1000 and WPC 2000 Wintriss Clutch Brake Controls - with no need for a separate control box. This reduces both the initial investment in equipment and the cost of installation.

Connect up to Four Pairs of Heads to One Control

Shadow 8's unique design enables you to protect multiple sides of a machine using a single control, one pair of cables, and up to 4 pairs of light curtains in series. You can protect both the front and back of your equipment as well as provide horizontal pass-through detection. Even a large machine can be guarded with up to 202" of protected zone to a single control providing an economical solution and minimizing installation time (for either the transmitter or receiver, the total length of the heads and interconnect cabling cannot exceed 110 feet).

Programmable Fixed Blanking

Fixed blanking windows disable one or more beams to allow stationary objects such as conveyors or work tables to remain in the sensing field. You simply place the obstruction between the transmitter and receiver and turn the key-lock switches on the control. Shadow 8 senses the presence of the object and "blanks" the obstructed beams. The Individual Beam Indicators (IBIs) light up to indicate which beams are blanked. When the object is removed, the system will not allow the machine to run until the control has been reprogrammed to "unblank" the beams. The first or the main segment must have a minimum of 7 to 9 consecutive beams (5.5" to 7") not blanked based on its height (e.g., the 12" main segment must have 7 consecutive beams (5.5") not blanked) and 2 consecutive beams in each extension must not be blanked.

Floating Blanking Window

Shadow 8 also enables you to set a floating blanking window, one beam wide, to allow objects smaller than 1", such as air-ejected parts, to pass through the light curtain in a random pattern without interrupting operation. This can also be useful when air or hydraulic lines need to pass through the field. You can use both floating and fixed blanking simultaneously.

3rd Party Verifications

Instead of saying "designed to meet", at Wintriss we felt it was important to subject our systems to the toughest third party certifications. Shadow 8 has undergone independent testing and certifications by Underwriters Laboratories (NRTL/C) to CAN/CSA 22.2 No. 14 and CAN/CSA 22.2 No. 0.8 and by TÜV to Category 4 CE/IEC 61496-1 and CE/IEC 61496-2. Shadow 8 complies with OSHA 1910.217, ANSI B11.1-2009, ANSI B11.19, CSA Z142 and CSA Z432.

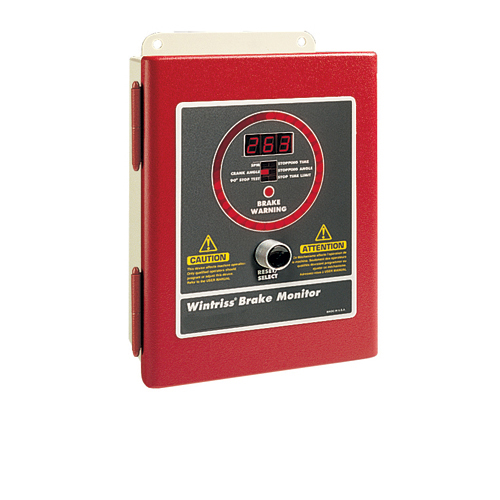

Brake Monitor/Safety Switch/Custom Panels

Wintriss Brake Monitor

Full-featured, control reliable stopping performance monitor. Monitors press stopping performance

The Wintriss Brake Monitor is important to the safe application of machine guards such as safety light curtains. It warns the user when stopping time exceeds safe limits.

- Meets ANSI B11.1-2009 control reliability requirements

- Real-time stop-time monitor

- Digital readout for SPM, crank angle, stopping angle, stopping time, or limit

- Has the ability to perform a 90° stop-time test at the touch of a button

- Brake warning indicator light

- Crank angle "clock" style display

Wintriss Safety Switch

This rugged safety switch can be used as a safety interlock on machine doors, covers, barrier guards, die blocks, etc.

- The operation key activates a direct opening mechanism to open the contacts and shut off control circuits when, for example, protective doors are opened on machine tools or other equipment

- Malfunctions and false operation prevented by special Operation Key

- Positive opening operation of 2 normally closed contacts -- compatible with the Wintriss Press Control's cross-checked pair of user-definable inputs

- Rugged metal construction

- Operation key is available in 2 mounting styles: Straight (shown above) and 90°

- Switch head rotatable in 4 possible mounting directions

- Wide temperature range specifications: -40 to 80°C

- Degree of protection of the switch box: IP67

- Certified by UL, CSA and TUV

Custom Consoles and Panels

Wintriss can build you a complete, custom, integrated, turnkey control package.

Wintriss can custom build a press-control console or panel tailored to your needs. Your integrated control system can combine any of the following:

Wintriss Clutch/Brake Control

|

|

Motor-control options

|

|

Other options for productivity:

- SmartPAC® 2 , an advanced modular press automation control with many options.

- Shadow® 8 light curtains

|

|

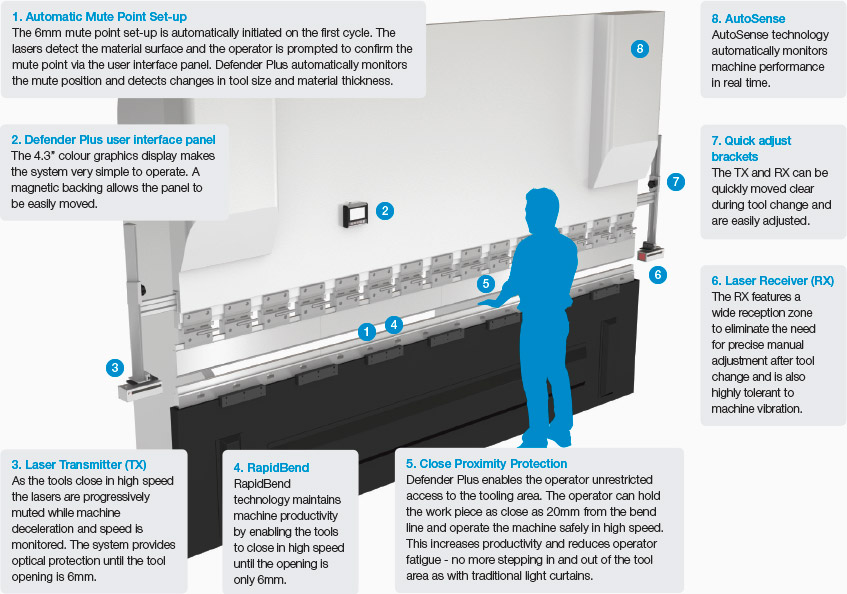

Defender Plus Press Brake Guarding System

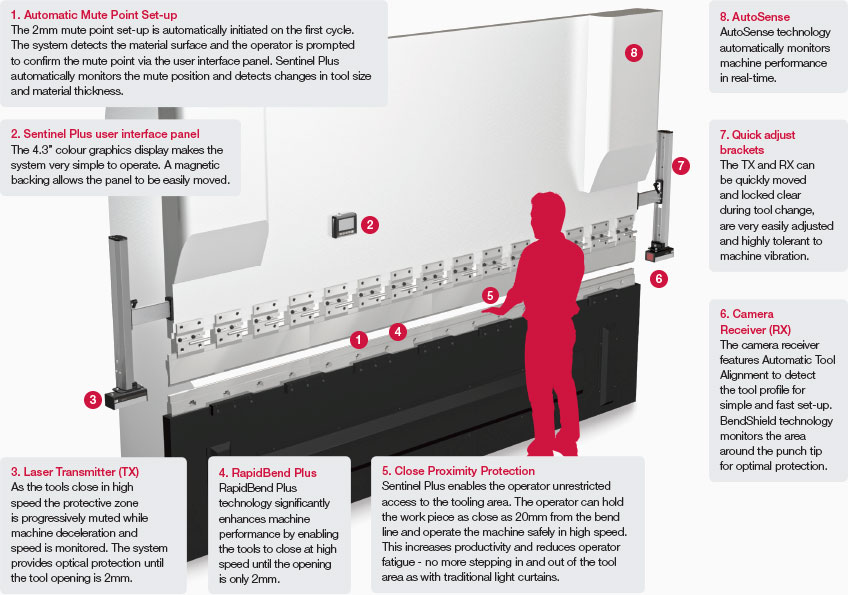

Sentinel Plus Press Brake Guarding System

Defender Plus Optical Protection

Defender Plus is a press brake guarding system designed for retrofit applications and provides a high level of operator protection while maintaining machine productivity and performance.

The Defender Plus laser transmitter and receiver are mounted to the upper beam of the press brake. A continuous dual laser field protects the zone directly below the punch tip allowing the operator to hold the work piece as the tools close at high speed. If an obstruction is detected the machine is automatically stopped.

This close proximity protection allows the operator unrestricted access to the point of operation for increased productivity and unlike traditional light curtains, reduces fatigue by enabling the operator to remain standing in the same position.

Sentinel Plus Faster Than Ever

Sentinel Plus is the most advanced press brake guarding system ever designed for retrofit applications and is optimised for high speed performance machines. As a camera based system, Sentinel Plus delivers exceptional levels of protection, productivity and performance.

The Sentinel Plus Press Brake Guarding System includes RapidBend Plus technology that enables you to operate faster than ever before. RapidBend Plus works with flat sheets and box profile parts so the machine can close at high speed right down to 2mm above the material to significantly boost your productivity.

Defender Plus

Sentinel Plus

Defender Plus Key Features

- Mute point is easily set according to the material position and optically verified automatically on every cycle.

- Multiple modes available to suit any shape and profile of work piece. At the press of a button simply select a mode that best suits each bend job to achieve the best level of productivity and performance.

- Graphical user interface panel displays system and machine status in real time. Simple to follow instructions and messages make the system very easy to operate.

- Automatic monitoring of speed and stopping performance.

- Quick adjust brackets are simple to set-up with adjustment after tool change taking only a matter of seconds.

Sentinel Plus Key Features

- Mute point is easily set according to the material position and optically verified automatically on every cycle.

- Graphical user interface panel displays system and machine status in real time. Simple to follow instructions and messages make the system very easy to operate.

- Multiple modes available to suit any shape and profile of work piece. At the press of a button simply select a mode that best suits each bend job to achieve the best level of productivity and performance.

- Integrated status LEDs on the TX and RX for simpler and faster set-up and adjustment.

- Automatic monitoring of speed and stopping performance.

- Quick adjust brackets with tool lock to keep the transmitter and receiver clear during tool change.

- Automatic Tool Alignment for simple tool change that takes only a matter of seconds.

- Special Tools Mode automatically detects and adjusts for any size and profile tool.

- Optional monitoring of additional machine safety elements including emergency stop buttons plus side and rear gate interlock switches with real time status displayed on the user interface panel.

- Dual guarding option - install laser protection and a third party light curtain for even more flexibility. Simply select the protection that best suits the bend job.