Specific Press Brake Dies

Die Sets

All Specific Press Brake Dies are made from prehardened die steel hardened to a mean 265 Brinell hardness, which is standard in this industry for application unless otherwise indicated.

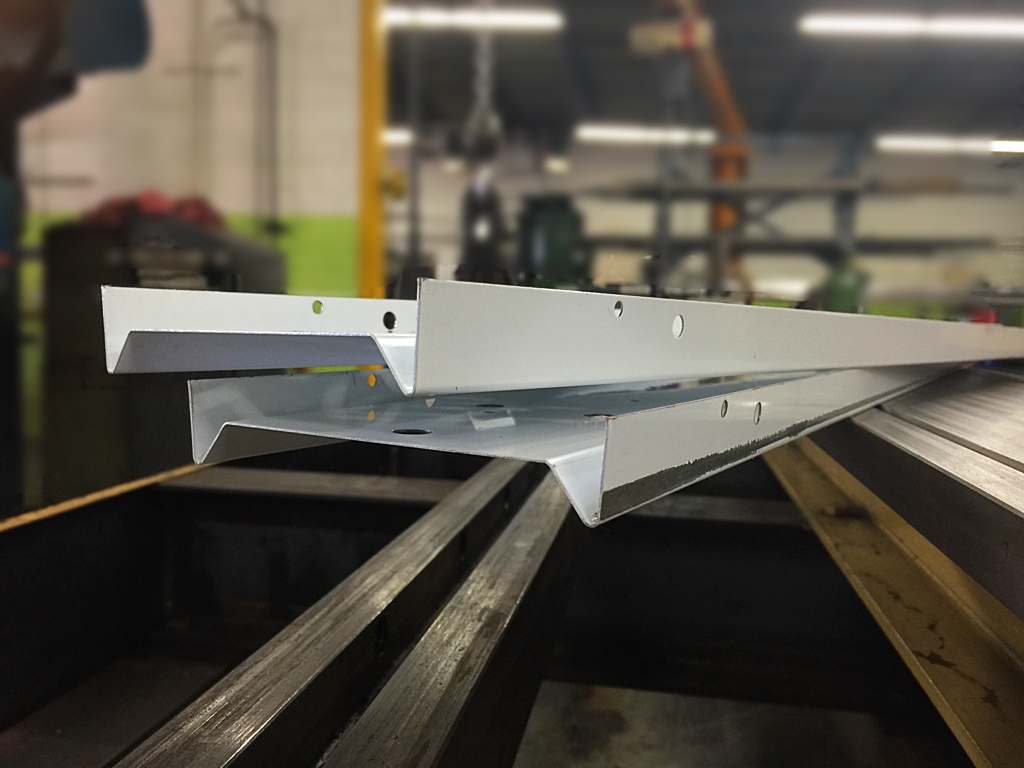

We produce many different types of die sets, including:

- Offset Die Sets

- Joggle Die Sets

- Channel Die Sets

- Curling Die Sets

- Wiping Die Sets

- Rib Forming Die Sets

- Radius Forming Die Sets

- Special Offset Die Sets

- Hemming / Standing Seam Die Sets

Punch and Dies

All Specific Press Brake Dies are made from prehardened die steel hardened to a mean 265 Brinell hardness, which is standard in this industry for application unless otherwise indicated.

We produce many different types of punches & dies, including:

- 90 Degree Forming Punches & Dies

- 90 Degree Air Forming Punches & Dies

- Gooseneck Punches

- Acute Forming Punches & Dies

- Flattening Dies

- Pivot Form Vee Dies

Multi-Vee Block Dies / Adjustable Air Forming Die

|

Die No.

|

Block Size

|

4 Die Openings

|

|||

|

2-2MV4

|

2.250

|

0.500

|

0.750

|

1.000

|

1.250

|

|

2-7MV4

|

2.750

|

0.625

|

0.875

|

1.125

|

1.500

|

|

3-2MV4

|

3.250

|

0.750

|

1.000

|

1.500

|

2.000

|

|

3-7MV4

|

3.750

|

0.875

|

1.125

|

2.000

|

2.500

|

|

4-2MV4

|

4.250

|

1.000

|

1.500

|

2.000

|

3.000

|

|

4-7MV4

|

4.750

|

1.000

|

1.250

|

2.500

|

3.000

|

|

5-2MV4

|

5.250

|

1.000

|

2.000

|

3.000

|

4.000

|

|

5-7MV4

|

5.750

|

1.250

|

2.000

|

3.000

|

4.000

|

|

6-7MV4

|

6.750

|

1.500

|

2.500

|

3.500

|

5.000

|

|

7-7MV4

|

7.750

|

2.000

|

3.000

|

3.500

|

6.000

|

|

10MV4

|

10.00

|

2.500

|

3.500

|

4.000

|

8.000

|

|

12MV4

|

12.00

|

3.000

|

4.000

|

5.000

|

10.00

|

3-Way Dies

|

Die No.

|

Block Size

|

3 Die Openings

|

|||

|

2-2MV3

|

2.250

|

0.500

|

0.750

|

1.000

|

|

|

2-7MV3

|

2.750

|

0.750

|

1.125

|

1.500

|

|

|

3-2MV3

|

3.250

|

1.000

|

1.500

|

2.000

|

|

|

3-7MV3

|

3.750

|

1.125

|

2.000

|

2.500

|

|

|

4-2MV3

|

4.250

|

1.000

|

2.000

|

3.000

|

|

|

4-7MV3

|

4.750

|

1.250

|

2.000

|

3.000

|

|

|

5-2MV3

|

5.250

|

2.000

|

3.000

|

4.000

|

|

|

5-7MV3

|

5.750

|

1.500

|

2.500

|

4.000

|

|

|

6-7MV3

|

6.750

|

1.500

|

3.000

|

5.000

|

|

|

7-7MV3

|

7.750

|

2.000

|

3.500

|

6.000

|

|

|

10MV3

|

10.00

|

2.500

|

4.000

|

8.000

|

|

|

12MV3

|

12.00

|

3.000

|

6.000

|

10.000

|

|

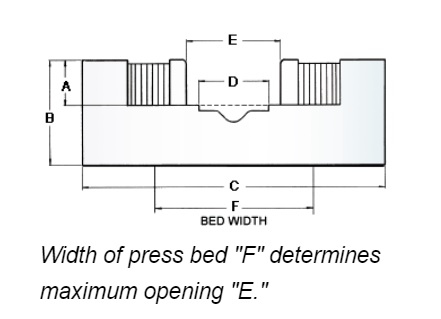

Adjustable Air Forming Die

Description:

The ADJ-77 is considered the most versatile air forming component to complement a press brake. From general forming, to bumping radii.

Width of press bed "F" determines maximum opening "E."

|

Die No.

|

A

|

B

|

C

|

D

|

E

|

F

|

|

ADJ-77-1

|

1-5/8

|

2-7/8

|

8

|

NONE

|

1/4-3-1/2

|

3-1/8

|

|

ADJ-77-2

|

2-1/4

|

4-1/8

|

12

|

NONE

|

1/2-5

|

5

|

|

ADJ-77-3

|

2-7/8

|

5-3/4

|

16-1/4

|

3-1/4

|

3-8

|

8

|

|

ADJ-77-4

|

3-1/4

|

7

|

19-1/2

|

4-1/4

|

5-10

|

10

|

|

ADJ-77-5

|

4-1/4

|

10

|

20-1/2

|

5-1/4

|

5-12

|

12

|

|

ADJ-77-6

|

6-3/4

|

10-1/2

|

28

|

7-3/4

|

8-15

|

15

|

Wila ''New Standard'' Tang Sleeve

The Wila Tang Sleeve features:

- Convert American tooling to a "New Standard" style Tooling

- No need for an adapter that consumes shut height

- Allows use of existing special applications

- Lower cost tooling

Notes:

Punch shoulders must be a minimum of 7/16".

Not to be considered Precision Tooling.

Shoulder mount style only.

Description:

The Specific Press Brake "New Standard" (Wila) Tang Sleeve allows endless forming possibilities in your Wila style press. The sleeve enables American style tooling to be adapted to run in a Wila style press brake.

Deflection Compensation Holder

This high-precision fixture features:

- Eliminates shimming

- Easy, single central-point adjustment

- Integrated, aperture read-out gauge

- Reliable, single-wedge design

- Top-cap eliminates infiltration of abrasive particles

- Requires virtually no training

- Low-profile design consumes minimal die "open space”

- Helps ensure constant, accurate angle bending.

Description:

The Specific Press Brake Ø-DFLX Deflection Compensation Holder is a single central-point adjustment device to compensate for elastic deformation of the press brake when under bending load.

Fast, easy, accurate crowning adjustment over the full length of the die. Makes set-up quick and flexible - helps profitability meet the demands of today's sheet metal industry. The need to manufacture in a variety of dimensions, bent angles, materials, thicknesses and detail geometry.

Multi-Point Adjusting Compensation Die Holder Series II

This high-precision fixture features:

- Easy, Single central point adjustment

- Independent adjustment thru entire length of the die

- Eliminates shimming

- Integrated, aperture read-out gauge

- Top-cap eliminates infiltration of abrasive particles when running materials that generate slag, galvanic debris, etc.

- Requires virtually no training

- Low-profile design consumes minimal die "open space”

- Helps ensure constant, accurate angle bending for the highest quality production

Description:

We all know and understand the problems that occur with forming on a press brake. The main concern is the compensation of deflection which jeopardizes the end result of your forming standards. Specific has developed a solution to this problem. The Ø-DFLX Series II compensation holder is a precision adjustment device that not only compensates for crowning at a single central point, but takes advantage of our patented dual-wedge design allowing for independent adjustment at every 8 inches to compensate for inconsistencies in the press, worn tooling, or to aid in side by side staged applications.

Fast, easy, accurate crowning adjustment over the full length of the die. Makes set-up quick and flexible - helps profitability meet the demands of today's sheet metal industry. The need to manufacture in a variety of dimensions, bent angles, materials, thicknesses and detail geometry.

PDF Downloads:

Die Lifter Series

The Die Lifter Series features:

- Easy installation and removal of tools.

- Reduces setup and teardown time.

- Quick and easy installation.

- Durable design.

- Can be installed into new and existing tooling.

Description:

Keep production rolling with Specific Press Brake Die Lifter Series. The Die Lifter Series is designed to minimize effort when installing and removing tools into your press brake. Be sure to consider Die Lifters when purchasing a new die holder or a large die. We can also install Die Lifters into your existing holders and dies.

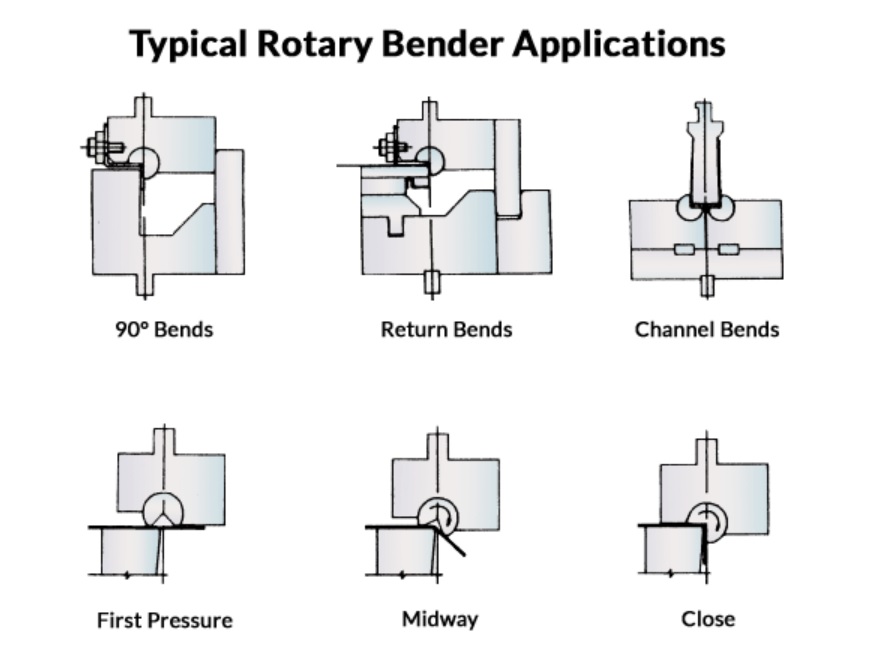

Rotary Bender

| Model No. | Rocker Diameter | Range of Material | Min. & Max. Flange Length-0D |

| PCM-1 | 1" | 22-14 Ga. (.030-.075) |

7/16" - 2" |

| PCM-15 | 1-1/2" | 13-11 Ga. (.089-.120) |

5/8" - 2" |

| PCM-2 | 2" | 10-8 Ga. (.134 - .164) |

13/16"-2" |

Ram Adapters / Die Holders

Description:

It is sometimes necessary to fill die space if RAM adjustment is insufficient or if application exists. In either case, RAM adapters are mounted to the RAM of the press. Height and width are suited to your condition.

Any die holder 4" high or over can be furnished with half moon burnouts for mounting.

Series 200

|

Number

|

A

|

B

|

|

200A

|

2 c.u.

|

1-1/2 c.u.

|

|

200B

|

2 c.u.

|

2 c.u.

|

|

200C

|

2 c.u.

|

3 c.u.

|

|

200D

|

2 c.u.

|

4 c.u.

|

|

200E

|

2 c.u.

|

5 c.u.

|

|

200F

|

3 c.u.

|

1-1/2 c.u.

|

|

200G

|

3 c.u.

|

2 c.u.

|

|

200H

|

3 c.u.

|

3 c.u.

|

|

200I

|

3 c.u.

|

4 c.u.

|

|

200J

|

3 c.u.

|

5 c.u.

|

|

200K

|

4 c.u.

|

2 c.u.

|

|

200L

|

4 c.u.

|

3 c.u.

|

|

200M

|

4 c.u.

|

4 c.u.

|

|

200N

|

4 c.u.

|

5 c.u.

|

|

200O

|

5 c.u.

|

2 c.u.

|

|

200P

|

5 c.u.

|

3 c.u.

|

|

200Q

|

5 c.u.

|

4 c.u.

|

|

200R

|

5 c.u.

|

5 c.u.

|

Series 600

|

Number

|

A

|

B

|

|

600A

|

2-1/4

|

3-1/2

|

|

600B

|

2-1/4

|

4-3/4

|

|

600C

|

2-3/4

|

3-1/2

|

|

600D

|

2-3/4

|

4-3/4

|

|

600E

|

3-1/4

|

3-1/2

|

|

600F

|

3-1/4

|

4-3/4

|

|

600G

|

3-3/4

|

3-1/2

|

|

600H

|

3-3/4

|

4-3/4

|

|

600I

|

4-1/4

|

3-1/2

|

|

600J

|

4-1/4

|

4-3/4

|

|

600K

|

4-3/4

|

3-1/2

|

|

600L

|

4-3/4

|

4-3/4

|

|

600M

|

5-1/4

|

3-1/2

|

|

600N

|

5-1/4

|

4-3/4

|

|

600O

|

5-3/4

|

3-1/2

|

|

600P

|

5-3/4

|

4-3/4

|

|

600Q

|

6-3/4

|

3-1/2

|

|

600R

|

7-3/4

|

3-1/4

|

|

600S

|

10

|

3-1/2

|

|

600T

|

12

|

3-3/4

|

Safe-Sert

Description:

Specific SAFE-SERT inserts can retro-fit and convert any standard-tongue press brake die to a safety-tongue configuration.

SAFE-SERT fittings (Patent Pending) insert flush into holes machined in the side of the tongue and tangential to its top edge. Only the profile of each SAFE-SERT's safety tab protrudes from the tongue to engage the press clamp. Each SAFE-SERT is friction-secured with a countersunk Allen head screw.

The machined through-holes allow SAFE-SERTs to be switched to either side for use on reversible gooseneck configurations. SAFE-SERTs can be installed in tooling segments as short as 1" to help prevent drop-outs.

Urethane Die Film

The forming of bends using press brake tooling involves drawing the material into a die. As the material draws over the radii of the die some amount of abrasion to the material is bound to occur. In many cases the finished part will be used in a setting where cosmetics are important. Consequently, eliminating or at least minimizing the abrasion at the source saves a costly secondary operation.

Specific Press Brake Dies' no-mar urethane die film is economical and convenient. Available in various sizes x 100' long roll, different thickness' and strength durometer. Our White No-Mar urethane die film is .015" thick and available in 4" & 6" widths. Our Blue No-Mar urethane die film is .022" thick, also in 4" & 6" widths, is of a more durable durometer and has been tested to last 3 times as long as the white.

Simply cut a length long enough to cover the working area of the die and tape it in place. Material to be formed is the laid on top of the die film and bending proceeds. Our urethane die film prevents the part from coming in contact with the die therefore eliminating any marks. Being extremely durable the Die Cover Film will perform for numerous parts before having to be replaced with a new length.