Wintriss Die Protection and Press Automation

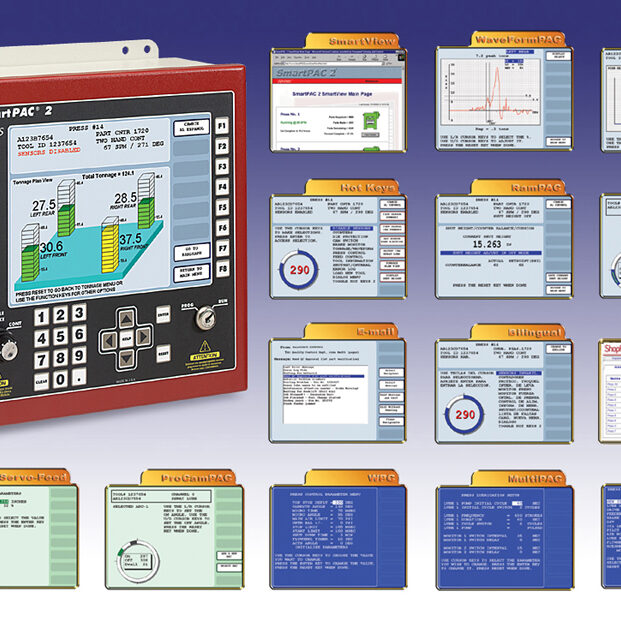

SmartPAC 2

Wintriss Controls is a leading manufacturer of press automation, die protection and safety controls for metal stamping and forming industries; and data collection systems for all discrete manufacturing. We provide seminars for all products and OSHA compliance along

with plant surveys. These products, which leverage Wintriss’ 50+ years of experience in the metal stamping industry, are known for their proven performance and rugged dependability in the toughest factory environments. Wintriss equipment is backed by attentive service, timely repairs, and comprehensive spares inventories. A toll-free hotline gives customers immediate access to technical support experts for product information and applications assistance.

SmartPAC2 controls and monitors your press. View the status from anywhere in the world. Wintriss Controls has raised the bar once again with the introduction of the SmartPAC 2 Press Automation Controller. The SmartPAC 2 features a large color screen, advanced communications, superior graphics and numerous performance enhancements.

Die Protection Systems

The DiPro1500 helps to prevent costly repairs and press downtime. With sensors installed in and around the tool, malfunctions such as improper part ejection, misfeeds and material buckling are detected before die damage occurs. If there is a malfunction, the system signals the press to stop.

The Wintriss Controls Group pioneered the use of electronic sensors for die protection and introduced the first commercial die protection systems more than 50 years ago. Wintriss remains the leader in die protection systems and technology.

SPECIFICATIONS

- Saves settings for 200 tools

- 6 programmable sensor inputs

- Compatible with the Wintriss DSI 2 Die Protection Sensor Interface.

- Individual "ready" signals for each sensor

- Allows "on-the-fly" adjustments

- Sensor actuation signals shown on screen

- Individual stop selection for each sensor (emergency or top stop)

- Ability to lock or password-protect settings

- Naming sensors improves troubleshooting

- Expanded on-screen error messages

- Parts, batch, and total-hits-on-a-tool counters

- LED display for press speed and crank angle

- Optional programmable cam switch with 4 or 8 channels

Tonnage Monitors

With strain links mounted on the press, AutoSet 1500 Plus

monitors press load on every stroke. If tonnage exceeds

either high or repeatability setpoints or press capacity,

AutoSet 1500 Plus signals the press to stop. In many applications, normal allowable process variations do not permit setting high setpoints tight enough to detect die malfunctions. Repeatability, the allow-able stroke-to-stroke variation in tonnage, however, can ignore these gradual variations and provide a very tight window to be set

from one stroke to the next. Die malfunctions such as misfeed, broken punches and ejection failure can easily be detected. Repeatability monitoring allows for tighter process control.

Shop Floor Connect

ShopFloorConnect is a shop floor data collection system from Wintriss Controls Group of Acton, MA. We have been manufacturing and installing electronic controllers on industrial machinery for over 60 years. We developed our first downtime data collection and efficiency reporting software product in 1985, and we've been perfecting it ever since. We have a unique skill set: Not only do we provide a robust and scalable OEE reporting product and an on-machine production tracking solution that is simple to install and user friendly, but our industrial controls experience gives us the expertise to seamlessly adapt our technology to your machinery.

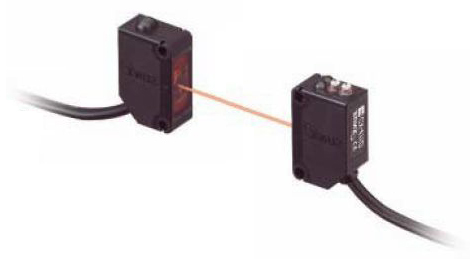

Die Protection Sensors

Wintriss Controls Group offers a complete line of die protection sensors for in-die use. These sensors are rugged, shock resistant, and sealed against the environment. Sensors are available to detect everything from end of coil, to misfeed, to part ejection. Inductive proximity sensors can detect, without physical contact, the presence of a metallic object. When power is applied to the sensor, an invisible sensing field emanates from the face of the sensor. A metallic object entering this field is detected by the sensor. The proximity sensors offered by Wintriss Controls Group are excellent sensors for in-die use. Sensing ranges and operating characteristics are unaffected by lubricants and other non-metallic contaminants. In addition, proximity sensors are the most accurate sensors commonly used for die protection. With trip-point repeatability as small as 0.0004 in (0.01 mm), they are more than accurate enough for detecting die malfunctions.

Sensor Interface Connection Hardware

The DiPro Sensor Interface (DSI 2) allows you to connect most electromechanical and discrete-output electronic sensors to your die protection control.

The DSI 2 is available with 8 or 16 sensor inputs, and features a built-in 24VDC power supply to power your sensors.

The DSI 2 has built-in pulse stretching on inputs 1-4 (also on inputs 9-12 on 16-input units) to stretch very fast signals (usually from part ejection sensors) out to a duration of 10mSec.

The DSI 2 is a flexible sensor connection solution. It is available with or without front- panel connectors for wiring individual sensors, along with a variety of larger connectors (including a heavy duty 19-pin M23 connector) for use with die-mounted junction boxes that allow you to connect up to eight sensors to the DSI with a single cable.

Wintriss offers a complete line of sensors and connectivity products including proximity and photoelectric sensors, die-mountable junction boxes, cables, and connectors.

The DSI 2 is compatible with all versions of SmartPAC 2, SmartPAC 1, and DiPro 1500.